Home > Products > Slings > Wire Rope Slings

Wire Rope Slings

Wire Rope Assemblies

All of our wire rope assemblies are manufactured in-house by our fully qualified technicians and engineers. Each assembly is supplied with full traceability and test certificates in line with our ISO9001 Quality Management System and relevant international, British and local standards.

Our production of wire rope slings and assemblies ranges from 2mm to 152mm diameter, available in galvanized, ungalvanized, stainless steel and plastic covered wire rope.

Single and Multiple Leg Wire Rope Slings

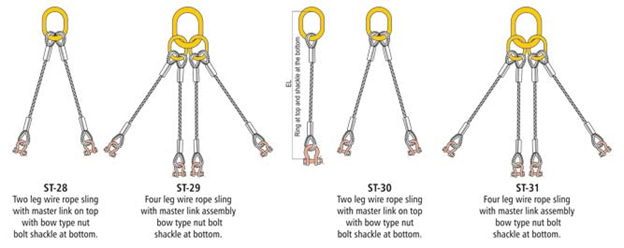

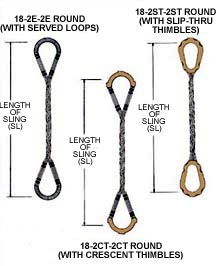

Wire rope slings and assemblies are the most common and rugged slings used today. This category of slings can be made in single, double, triple and quadruple leg configurations. Wire rope slings having two or more legs are often called "bridles". Wire rope slings can also be braided into multiple parts making them more flexible and able to handle more capacity by increasing the diameter of the sling.

Our sling catalog makes ordering easy because you can select sling sizes and lengths by dimensions or capacity. For information and pricing, contact us.

Single Leg wire rope sling

Features:

8-part braided wire rope sling

Features:

Two, three, and four leg bridle wire rope slings

Features:

Wire Rope Accessories

Safety Services Group provide a wide range of wire rope end terminations and fittings to suit all wire rope and rigging requirements.

In addition to our standard range, we hold Talurit, Crosby and Gunnebo lifting agency agreements, each offering a high quality range of wire rope fittings and lifting gears. All of our fittings are sourced from approved factories worldwide and are fully supported by full quality control processes and systems.